I bit the bullet and finally decided to get a engine and attempt the SR swap. A couple of months ago me and three other people, who all have much more automotive mechanical ability than I do, pulled a KA from a hatch and got rid of it and pulled another KA from a coupe and swapped that into the hatch during a weekend. Participating in this swap was very useful in helping me to remove my KA and the knowledge that I got will be useful in helping me to perform my SR swap as well. After reading other peoples build threads I don't think I can call mine a "build" because I'm just shooting for the bare-bones basic SR swap. I plan to swap out as many gaskets as I can, the front/rear main oil seals, waterpump, thermostat, spark plugs and possibly add a few aftermarket parts over their stock counterparts. If somebody sees something that I am doing wrong by all means chime in because I need all the help I can get.

*EDIT**********************************

I decided to put up a quick table of contents for those basic SR swap guys who just need a answer to that one question or just need to see that one pic to verify something.

PAGE 1------------------------------------------------

Introduction and engine breakdown(no pics).

Front oil seal replacement

Intake manifold breakdown

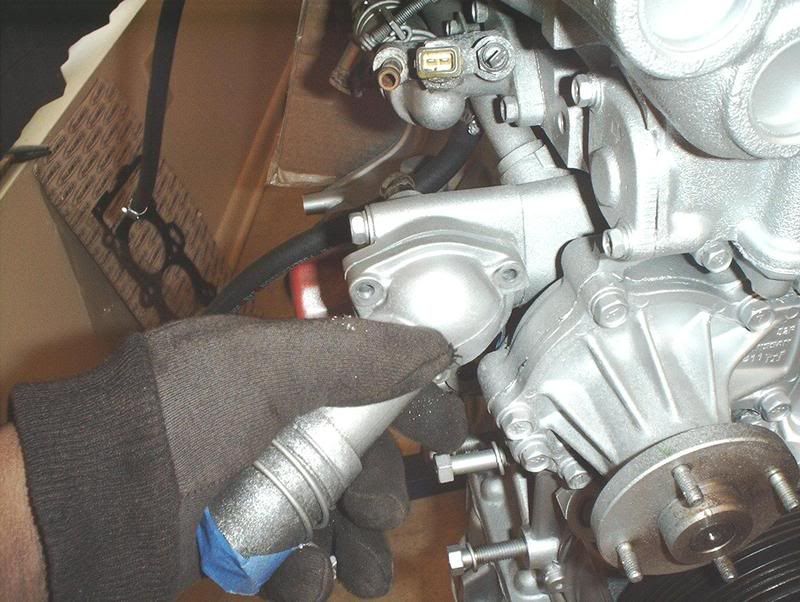

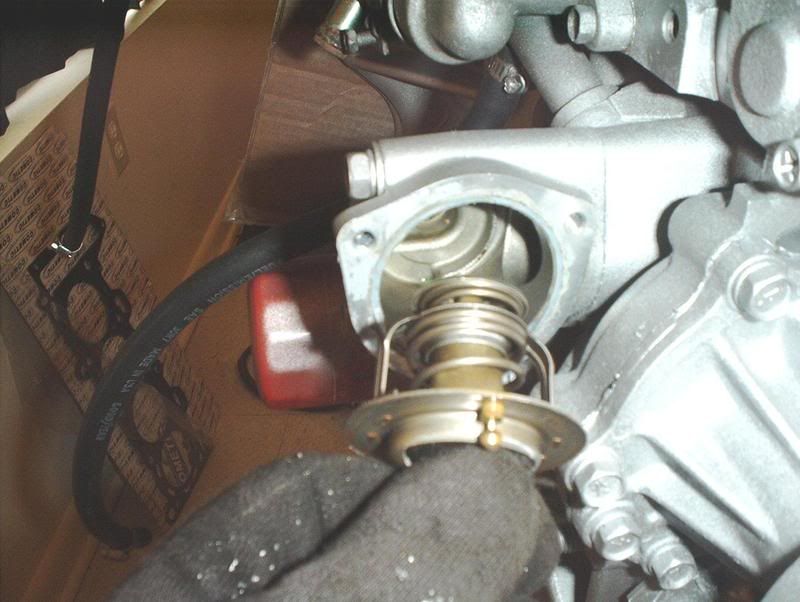

Thermostat replacement

Engine paint

Engine cleaning

Aluminum steering bushing install

PAGE 2------------------------------------------------

Heater hose installation

Engine bay painting

Powersteering pump problem #1

Sidemount intercooler

PAGE 3------------------------------------------------

Water pump installation

Water pump aftermarket pulley installation

Upper and lower radiator hose install

Speed sensor swapout

Intake manifold gasket install

CAS(Crank angel sensor) Replacement

Vacuum hose replacement

Turbo oil return hose install

Dipstick swapout

Fuel injector seal replacement

Fuel regulator install

Oil filter sandwich plate...YOU FAILED EBAY!!!!

PAGE 4-----------------------------------------

Rant Of The Day!!!

Coolant temp sensor replacement

Coolant gauge sensor replacement

Alternator aftermarket pulley install

Vacuum hose install(intake manifold)

Fuel injector seal replacement cont.

Fuel rail install

CAS cover swapout

Turbo breakdown OEM T-25

Turbo gasket install

PAGE 5-----------------------------------------

Water outlet/neck gasket install

Bolt/nut replacement with part #'s

PAGE 6-----------------------------------------

Altima fans vs. Permacool???

Altima fan modifications(get a dremel!!!!)

Altima fan breakdown

Spark plug replacement

Altima fan modification cont.

Altima fan mounting to Koyo rad

Clutch pivot ball problem!!!

Transmission dust collar replacement

Transmission slave cylinder replacement

Wire harness clips part#

Transmission gasket replacement

Power steering pump problem #2

PAGE 7---------------------------------------------

Knock sensor replacement

Transmission gasket cont.

Transmission rear seal

Transmission mount install

Clutch pivot ball install

Clutch pivot fork

Turbo stainless steel line install

Transmission drain plug install

Motor/Engine mount install

Turbo lines install cont.

PAGE 8--------------------------------------------

Turbo manifold/outlet install

Turbo locking nuts install

Turbo manifold gaskets install

Rocker arm install

Transmission insulator mount install

Valvecover part#

Fuel line replacement

Greddy oil pan install

Oil strainer replacement

DiF Fan controller wiring

Valvecover install

Valvecover gaskets install

PAGE 9--------------------------------------------

Turbo manifold install cont.

Flywheel (no install)

DiF fan controller wiring cont.

PAGE 10------------------------------------------

Hotpipe/B.O.V. (no install)

Oil filter relocation kit install

Clutch (no install)

Power steering pump aftermarket pulley install

Power steering pump install problem #3

PAGE 11------------------------------------------

Valvecover install cont.

O2 sensor install

Boost controller (no install)

Wire harness (no install)

PAGE 12------------------------------------------

Power steering pump problem SOLVED!!!

Ignition grounding plate install

Water temp gauge install

Coolant/water line replacement under intake manifold

PAGE 13--------------------------------------------

Water temp gauge cont.

Clutch line (no install)

Gauge wiring for Boost/Oil pressure/Water temp

Engine install (no pics)

Steel braided Valvecover T lines install

Intake filter & MAF install

Altima fan fitment modification cont.

Downpipe (no install)

Shifter bushing install

Engine startup

PAGE 14--------------------------------------------

DiF fan controller problem #1

PAGE 15--------------------------------------------

Snap ring problems

Radiator feet part #

PAGE 17--------------------------------------------

DiF fan controller problem FIXED!!!!

***********************************************************

![Image]()

I got my engine in from JSA Motors. Everything was intact, no missing pieces or parts(MAF/Ignitor chip), no broken crank angle sensor and a complete uncut wiring harness. Shipping was swift and I was able to track it to my delivery point. My only complaint was that the block was a little grimey, they said they would clean it before strapping it to the skid.

![Image]()

![Image]()

S13 Redtop SR20DET

![Image]()

The transmission is intact and very clean...

![Image]()

no transmission crossmember but I can use my KA's crossmember.

![Image]()

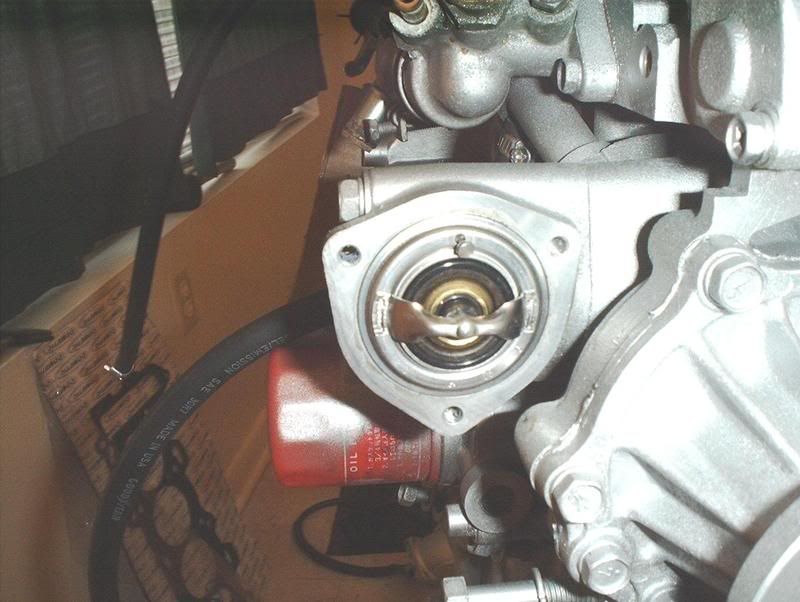

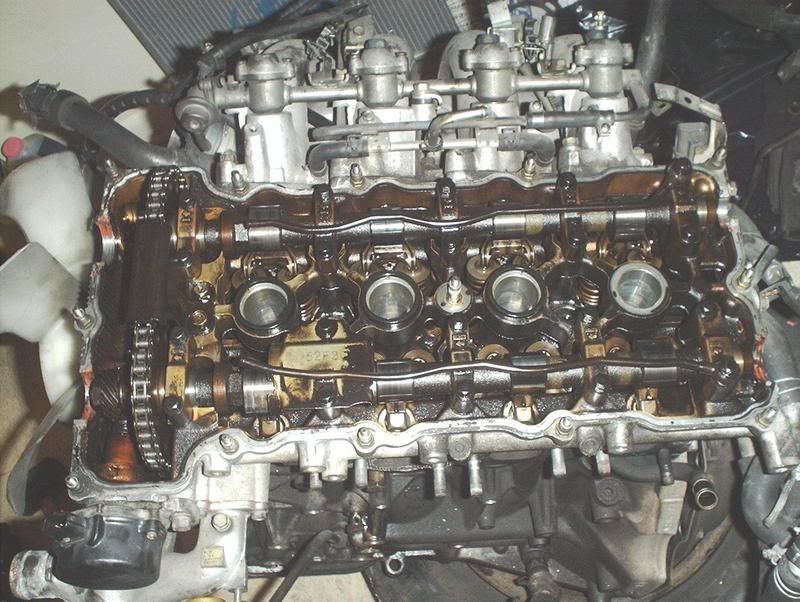

First thing I did was bust open the valve cover and inspect the internals, during my research I read some horror stories about people getting engines with rust and dirt inside.

![Image]()

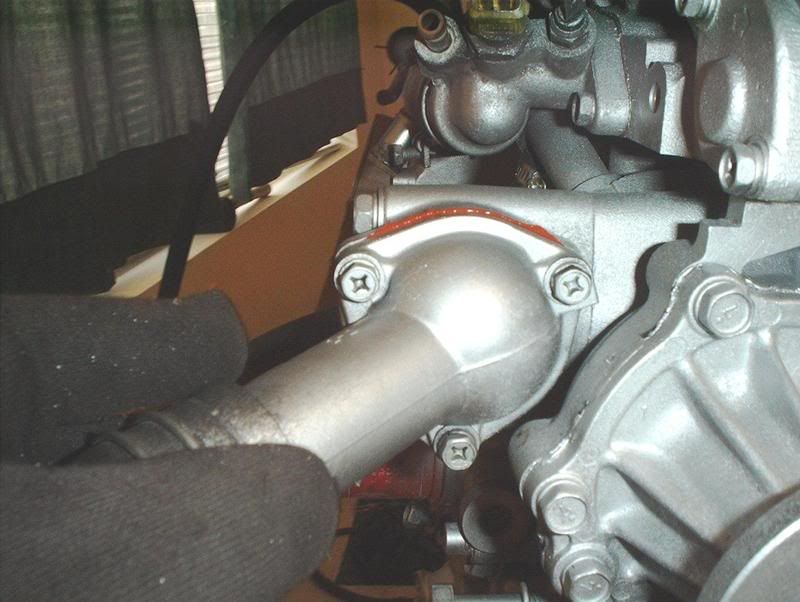

Apparently someone wasn't too fond of oil changes.

![Image]()

After that I completely broke down the exhaust side of the block. Striped everything!

![Image]()

Did the same for the intake side.

![Image]()

I removed the alternator, P/S pump, A/C compressor and the belt driven fan.

![Image]()

Broke out the bucket O' water, scrub brushes and Mean Green and started scrubbing away but I got tired of killing my back working on this engine on that old tire....

![Image]()

and borrowed a buds engine stand. This thing is a life saver!!!!!!

![Image]()

Look at all the stuff I pulled, hope I can remember where everything goes when I try to put it back.

![Image]()

After cleaning every knookie and cranny on this block I taped off everything I didn't want to get coated and laid down a couple of coats of high heat iron cast aluminum engine enamel to the block.

![Image]()

Turned out better that I thought it would.

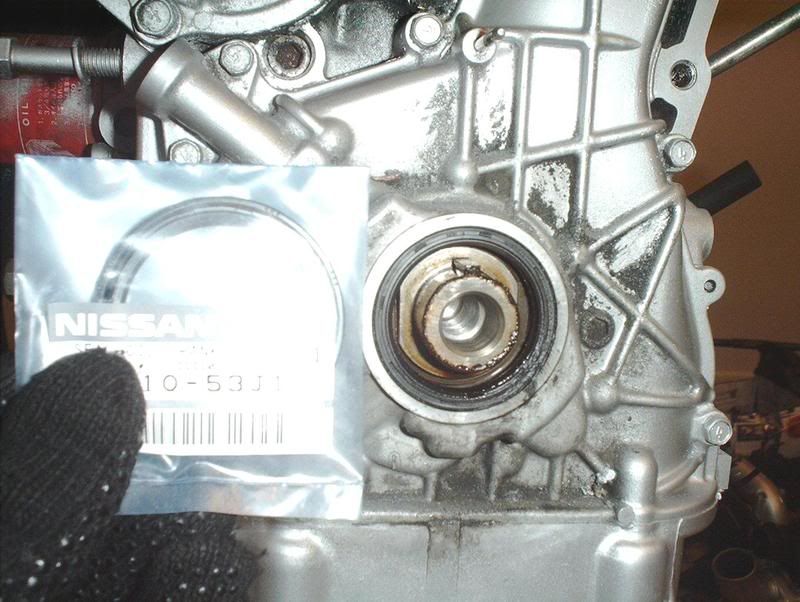

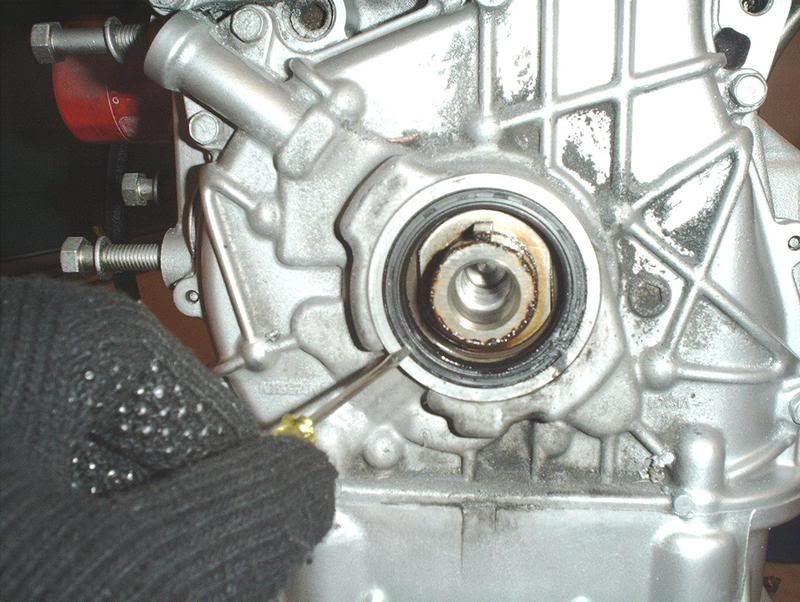

Now that I had everything cleaned up I turned my attention towards replacing parts. The first parts that I attempted to swap out were the main oil seals. I read up on what should be changed out on any basic engine swap and the oil seals were at the top of the list among other things such as oil pump, water pump, thermostat, spark plugs, various gaskets, motormounts, oil pan, etc.

FRONT OIL SEAL REPLACEMENT

Tools needed:

Socket wrench

Socket extension

27mm socket

Chain

1 transmission bolt

2 flywheel bolts

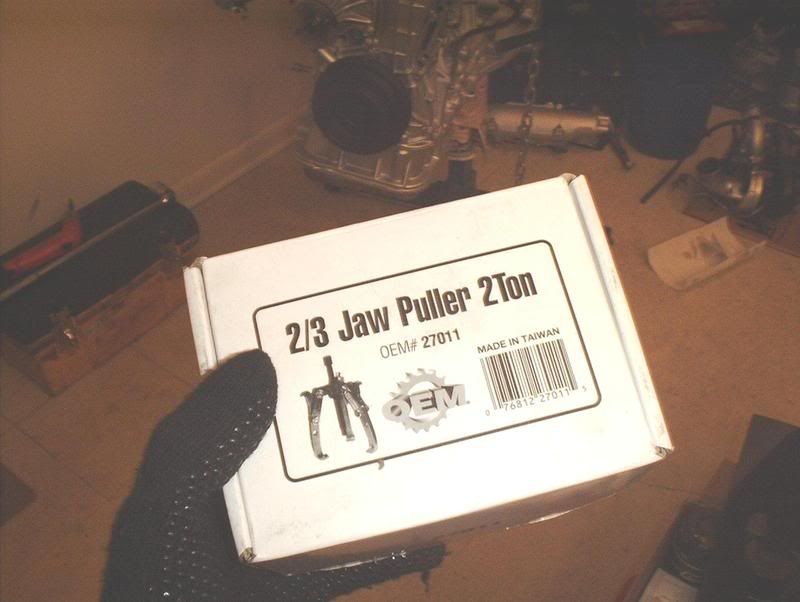

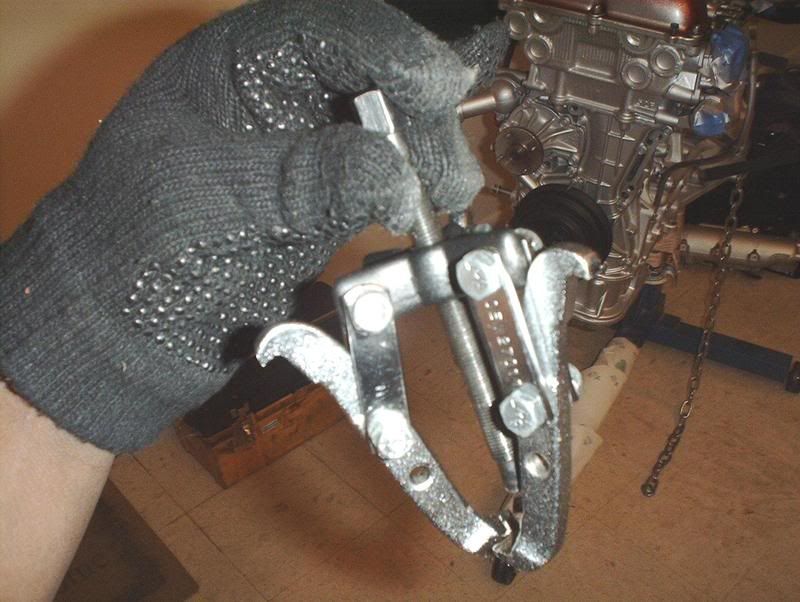

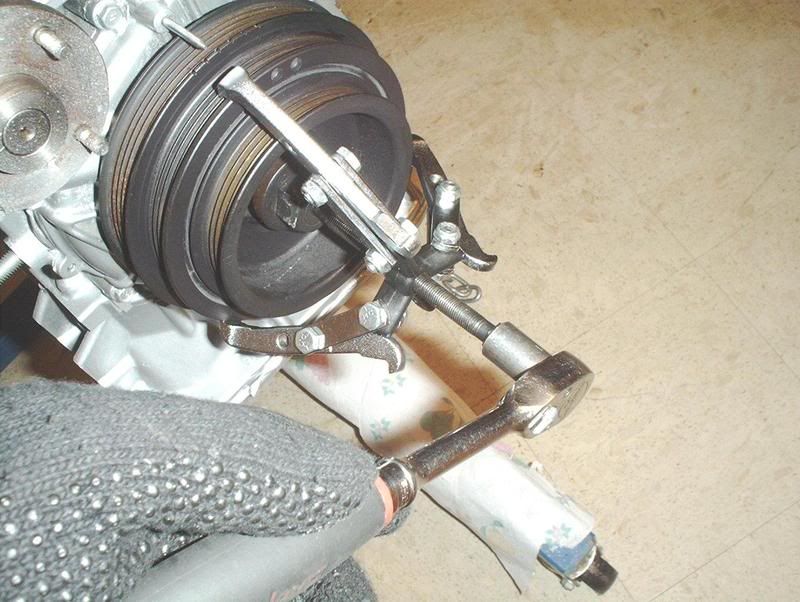

Pulley puller

Breaker bar

Seal puller or prybar/screwdriver

Seal driver

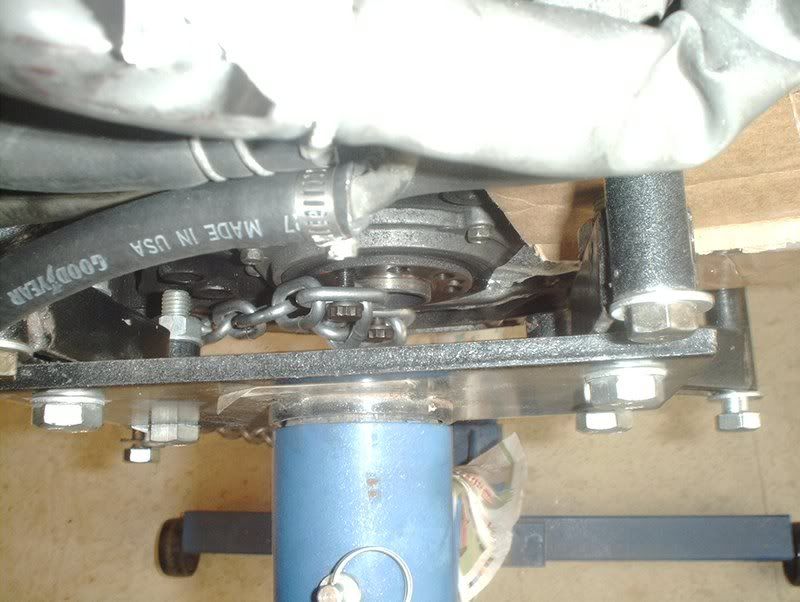

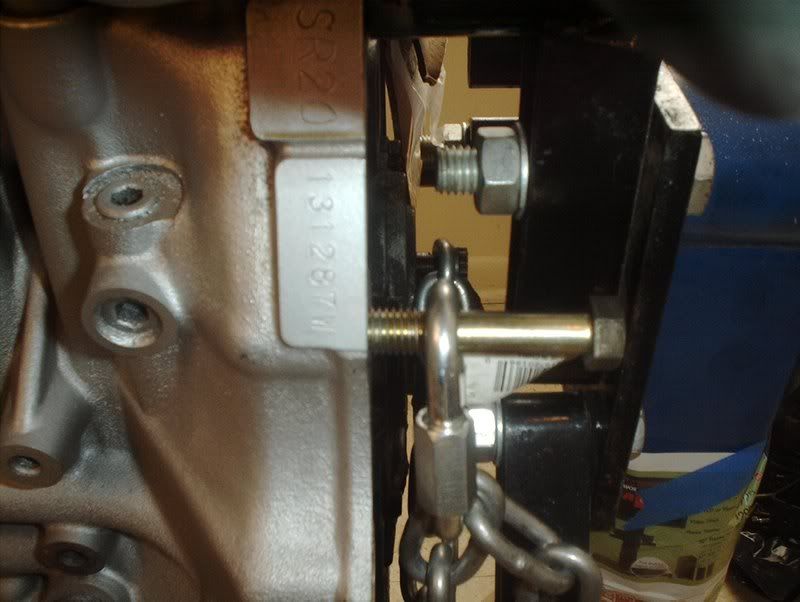

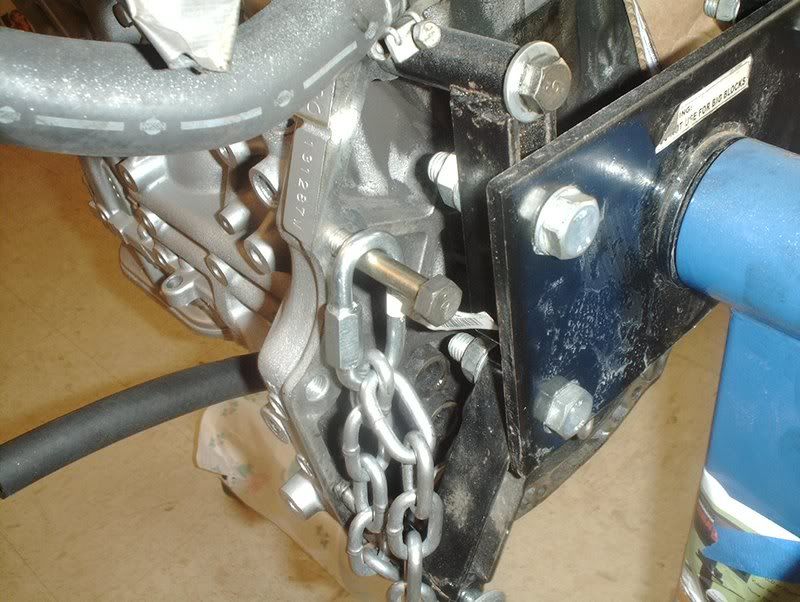

I want to change out the front and rear main seals but I can't get to the rear with the engine on the stand but the front is accesible. To get to it you need to remove the crank pulley but I couldn't get the pulley bolt off because the crank kept spinning when I tried to man up on it and I don't have any air tools so I had to think of another way. I decided to use the chain and the links that I used to pull my KA to help me.

![Image]()

I put two flywheel bolts through the chain and threaded them into the crank.

![Image]()

![Image]()

![Image]()

I looped the chain around the engine stand, stuck a transmission bolt into the link and threaded that into the transmission housing.

![Image]()

This kept the pulley from spinning.

![Image]()

This allowed me to use my 27mm socket and breaker bar to bust the crank pulley bolt loose.

![Image]()

![Image]()

Now I just need to get a pulley puller from the parts store to pop it off so I can replace the front main seal.

![Image]()

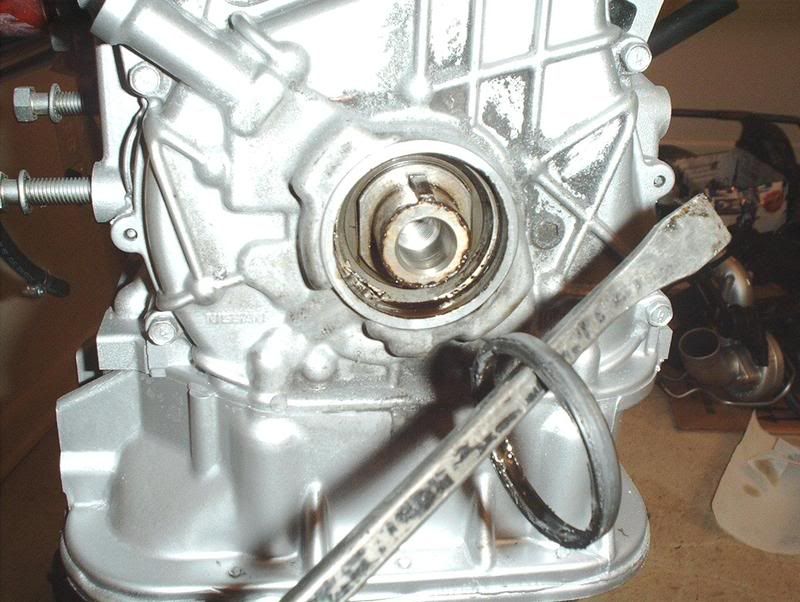

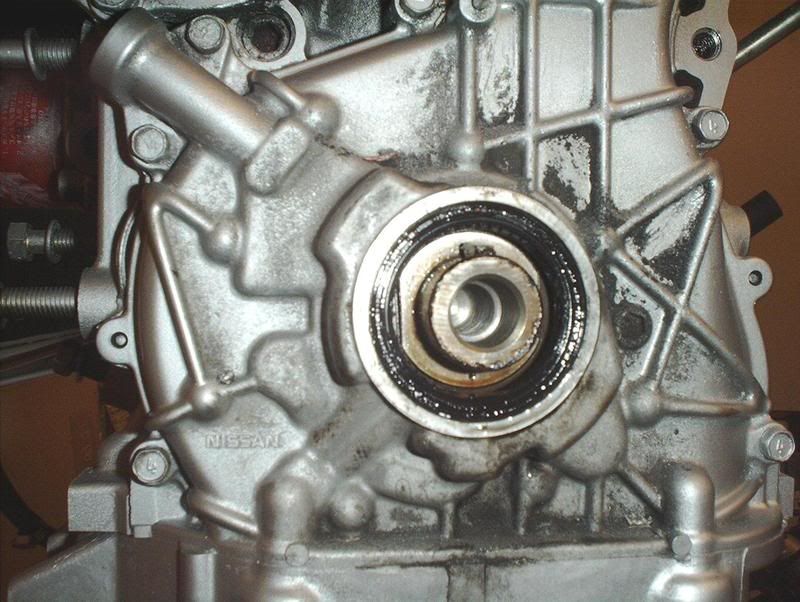

Here, you can see the rear main seal that I can't get to yet. Anyone know how it comes out? Does it pry out with a screwdriver or something?

*EDIT**********************************

I decided to put up a quick table of contents for those basic SR swap guys who just need a answer to that one question or just need to see that one pic to verify something.

PAGE 1------------------------------------------------

Introduction and engine breakdown(no pics).

Front oil seal replacement

Intake manifold breakdown

Thermostat replacement

Engine paint

Engine cleaning

Aluminum steering bushing install

PAGE 2------------------------------------------------

Heater hose installation

Engine bay painting

Powersteering pump problem #1

Sidemount intercooler

PAGE 3------------------------------------------------

Water pump installation

Water pump aftermarket pulley installation

Upper and lower radiator hose install

Speed sensor swapout

Intake manifold gasket install

CAS(Crank angel sensor) Replacement

Vacuum hose replacement

Turbo oil return hose install

Dipstick swapout

Fuel injector seal replacement

Fuel regulator install

Oil filter sandwich plate...YOU FAILED EBAY!!!!

PAGE 4-----------------------------------------

Rant Of The Day!!!

Coolant temp sensor replacement

Coolant gauge sensor replacement

Alternator aftermarket pulley install

Vacuum hose install(intake manifold)

Fuel injector seal replacement cont.

Fuel rail install

CAS cover swapout

Turbo breakdown OEM T-25

Turbo gasket install

PAGE 5-----------------------------------------

Water outlet/neck gasket install

Bolt/nut replacement with part #'s

PAGE 6-----------------------------------------

Altima fans vs. Permacool???

Altima fan modifications(get a dremel!!!!)

Altima fan breakdown

Spark plug replacement

Altima fan modification cont.

Altima fan mounting to Koyo rad

Clutch pivot ball problem!!!

Transmission dust collar replacement

Transmission slave cylinder replacement

Wire harness clips part#

Transmission gasket replacement

Power steering pump problem #2

PAGE 7---------------------------------------------

Knock sensor replacement

Transmission gasket cont.

Transmission rear seal

Transmission mount install

Clutch pivot ball install

Clutch pivot fork

Turbo stainless steel line install

Transmission drain plug install

Motor/Engine mount install

Turbo lines install cont.

PAGE 8--------------------------------------------

Turbo manifold/outlet install

Turbo locking nuts install

Turbo manifold gaskets install

Rocker arm install

Transmission insulator mount install

Valvecover part#

Fuel line replacement

Greddy oil pan install

Oil strainer replacement

DiF Fan controller wiring

Valvecover install

Valvecover gaskets install

PAGE 9--------------------------------------------

Turbo manifold install cont.

Flywheel (no install)

DiF fan controller wiring cont.

PAGE 10------------------------------------------

Hotpipe/B.O.V. (no install)

Oil filter relocation kit install

Clutch (no install)

Power steering pump aftermarket pulley install

Power steering pump install problem #3

PAGE 11------------------------------------------

Valvecover install cont.

O2 sensor install

Boost controller (no install)

Wire harness (no install)

PAGE 12------------------------------------------

Power steering pump problem SOLVED!!!

Ignition grounding plate install

Water temp gauge install

Coolant/water line replacement under intake manifold

PAGE 13--------------------------------------------

Water temp gauge cont.

Clutch line (no install)

Gauge wiring for Boost/Oil pressure/Water temp

Engine install (no pics)

Steel braided Valvecover T lines install

Intake filter & MAF install

Altima fan fitment modification cont.

Downpipe (no install)

Shifter bushing install

Engine startup

PAGE 14--------------------------------------------

DiF fan controller problem #1

PAGE 15--------------------------------------------

Snap ring problems

Radiator feet part #

PAGE 17--------------------------------------------

DiF fan controller problem FIXED!!!!

***********************************************************

I got my engine in from JSA Motors. Everything was intact, no missing pieces or parts(MAF/Ignitor chip), no broken crank angle sensor and a complete uncut wiring harness. Shipping was swift and I was able to track it to my delivery point. My only complaint was that the block was a little grimey, they said they would clean it before strapping it to the skid.

S13 Redtop SR20DET

The transmission is intact and very clean...

no transmission crossmember but I can use my KA's crossmember.

First thing I did was bust open the valve cover and inspect the internals, during my research I read some horror stories about people getting engines with rust and dirt inside.

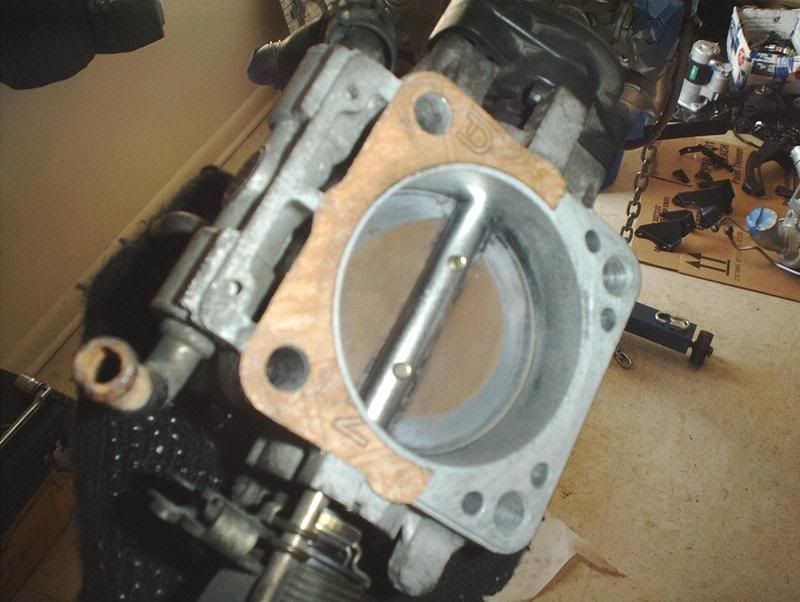

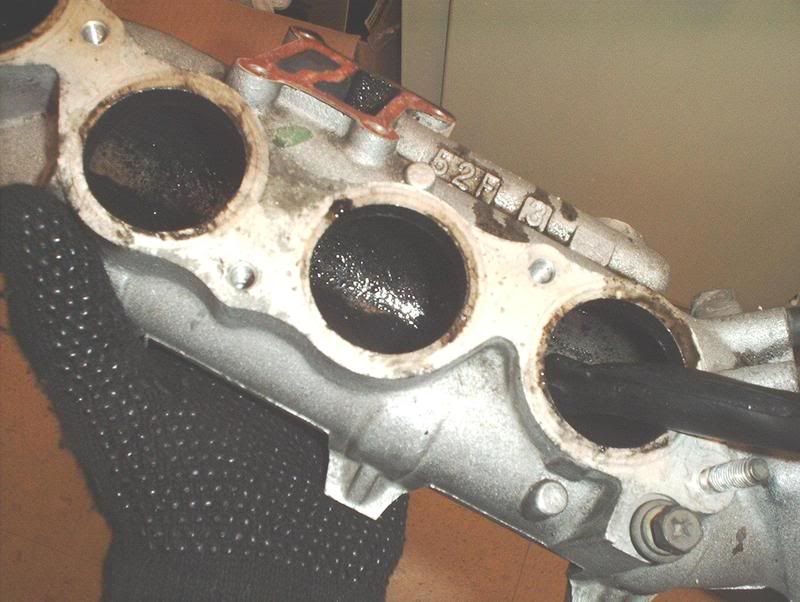

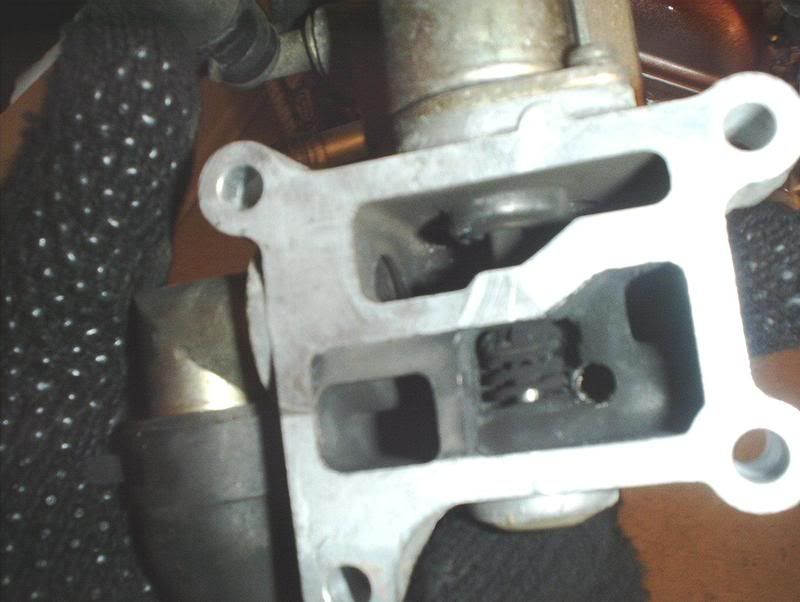

After that I completely broke down the exhaust side of the block. Striped everything!

Did the same for the intake side.

I removed the alternator, P/S pump, A/C compressor and the belt driven fan.

Broke out the bucket O' water, scrub brushes and Mean Green and started scrubbing away but I got tired of killing my back working on this engine on that old tire....

and borrowed a buds engine stand. This thing is a life saver!!!!!!

Look at all the stuff I pulled, hope I can remember where everything goes when I try to put it back.

After cleaning every knookie and cranny on this block I taped off everything I didn't want to get coated and laid down a couple of coats of high heat iron cast aluminum engine enamel to the block.

Turned out better that I thought it would.

Now that I had everything cleaned up I turned my attention towards replacing parts. The first parts that I attempted to swap out were the main oil seals. I read up on what should be changed out on any basic engine swap and the oil seals were at the top of the list among other things such as oil pump, water pump, thermostat, spark plugs, various gaskets, motormounts, oil pan, etc.

FRONT OIL SEAL REPLACEMENT

Tools needed:

Socket wrench

Socket extension

27mm socket

Chain

1 transmission bolt

2 flywheel bolts

Pulley puller

Breaker bar

Seal puller or prybar/screwdriver

Seal driver

I want to change out the front and rear main seals but I can't get to the rear with the engine on the stand but the front is accesible. To get to it you need to remove the crank pulley but I couldn't get the pulley bolt off because the crank kept spinning when I tried to man up on it and I don't have any air tools so I had to think of another way. I decided to use the chain and the links that I used to pull my KA to help me.

I put two flywheel bolts through the chain and threaded them into the crank.

I looped the chain around the engine stand, stuck a transmission bolt into the link and threaded that into the transmission housing.

This kept the pulley from spinning.

This allowed me to use my 27mm socket and breaker bar to bust the crank pulley bolt loose.

Now I just need to get a pulley puller from the parts store to pop it off so I can replace the front main seal.

Here, you can see the rear main seal that I can't get to yet. Anyone know how it comes out? Does it pry out with a screwdriver or something?