Project Progress: March 28 2007

Yes! Here you go!

Check it out guys...

I havent posted in a while but its because ive been working on the engine and taking pictures of the progress. Heres some pictures of what ive been currrently doing. This past week ive been going to my school and getting as much as possible done as the deadline draws near. Im still missing a few things here and there like the exhaust system, intercooler system, and other miscellaneous parts. So far ive just been putting back together what i have available and still waiting on my cam covers aswell. Im also still waiting on my income tax return refund and some paycheck money. Once i have this money, im buying some more things. :bigthumb

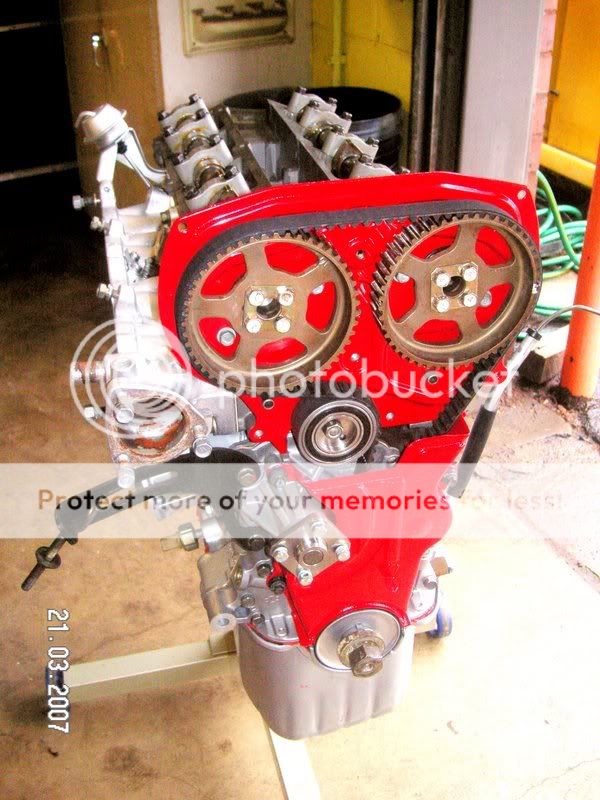

Rear cam gear plate goes on. Line it up and bolt it down! Install the tensioner and spring afterwards. Torque down the idler pulley if you havent done so already. Make sure you torque down everything according to OEM specifications!

Using a correct size allen wrench/key to rotate the tensioner in a way so that the timing belt can go on. Remember to set number one piston to top dead center and line up the marks on the crank and cam gears with their corresponding marks on the oil pump and rear cover plate.

Here it is installed! Make sure everthing is lined up correctly and nothing hits, like piston to valves.

Thats it!

Heres a nice black and white. :gapteeth

Picasa picture editing program to the rescue! Install lower timing belt cover.

Install the cam gear cover.

Heres a shot with the cam gear/timing belt covers back on. These were powder coated "Little Wagon Red."

Some more photo editing by me.

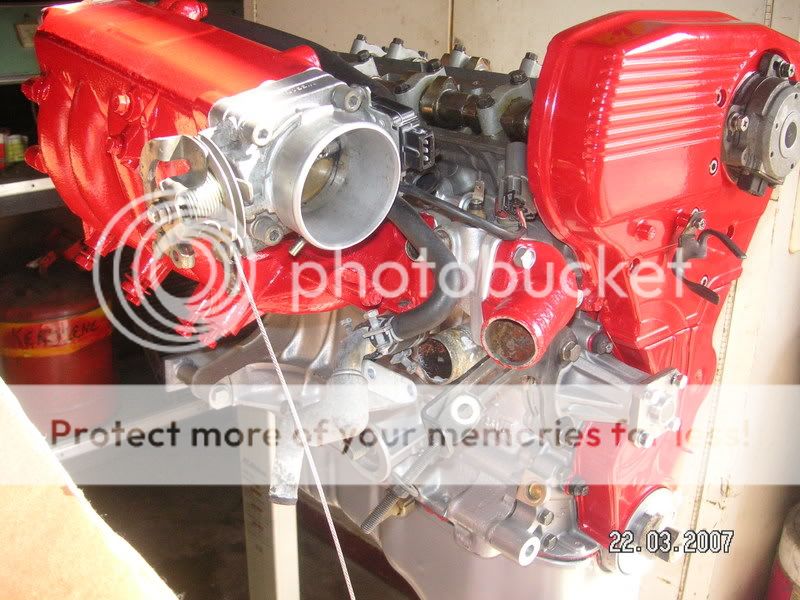

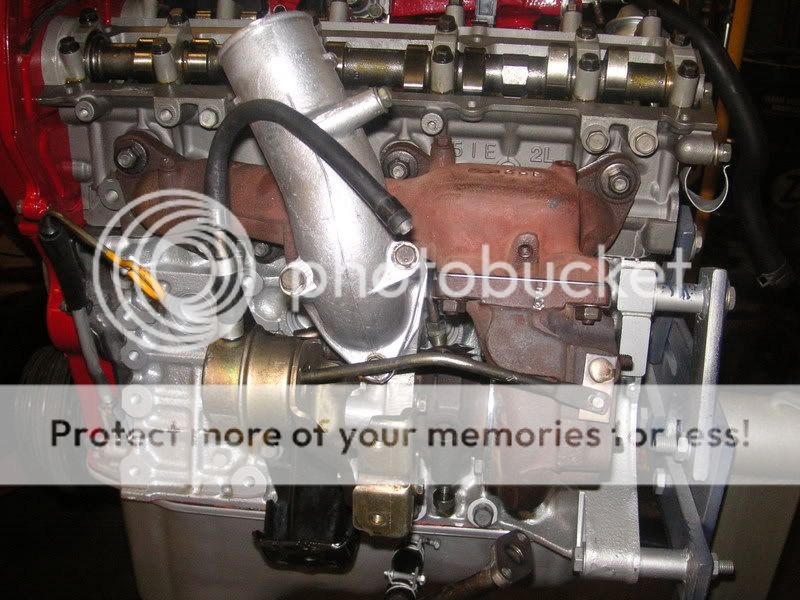

Heres a test fit of the remainder of the intake manifold. I also test fit the exhuast manifold and rebuilt CA t25 tubro. When installing the Crank/Cam Angle Sensor line up the spline in the camshaft with the shaft on the sensor. Do not force anything as it has become a common thing for this to break off! I dont know how you can break it off as it isnt rocket science but just ease it in, nice and slow. Finger tighten your three bolts that hold it to the cam cover and leave them loose incase you need to adjust timing later. :uhhuh

Black and white of the test fitting.

And i cant think of a better caption for this one.

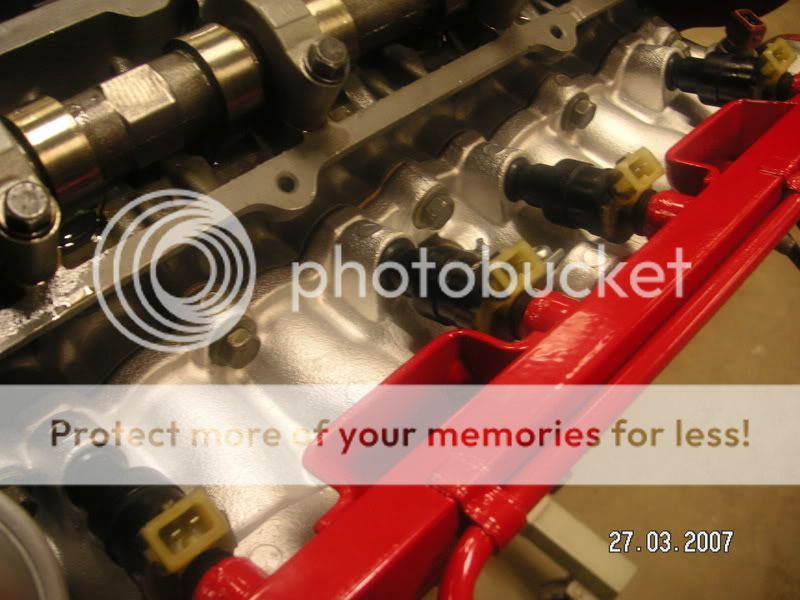

Nismo adjustable Fuel Pressure Regulator and my nicely redone fuel rail. Replaced the phillips style bolts with hex head because of less chance of stripping the bolt. Looks better this way.

Here i cleaned up the area in and around the thermostat housing. We still need the coolant temp sensors.

New thermostat and gasket...

Torque down the three bolts and youre done!

Rear collector cover for the intake manifold. This is so i have something of how the hoses were origanally.

Looking more complete! I still need to install the injectors and fuel rail. Hoses and lines are next.

Remember to install the coolant temp sensors as shown. I like taking lots of pictures! :biggrin

Heres a good shot of the powedercoated manifold. Its not the greatest but it sure looks really nice in the red. The whole scheme came out pretty damn good towards the end.

This ones a little easier to see.

A performance rebuilt CA18DET, $2600.00+ and counting... The day i get it running, priceless. :ylsuper

Incase i didnt mention it earlier, the oil pan is installed using Nissan RTV type sealant and new front and rear seals.

A closer look...

and another...

I installed the throttle body and tested the TPS but couldnt verify if it is truely working correctly. There was a break in the signal when testing with a DVOM but i havent tested it with a Digital Osiliscope so i cant deem it worthless just yet. I am going to go buy a new TPS and compare the new one to my old one.

Im soon coming up on a year since i got this engine and its not yet complete. By the end of the month, April, i plan on having it done. Im glad ill be getting help from others, teachers, and the school shop for this one.

:naughty Nice!

Heres the exhaust side without a manifold yet. Im currently shopping around for an aftermarket manifold and ive almost narrowed it down. Its most than likely going to be an "Ebay" manifold. I think im going with a Megan Racing turbo outlet and flex downpipe. Any ideas?

Cornered away...

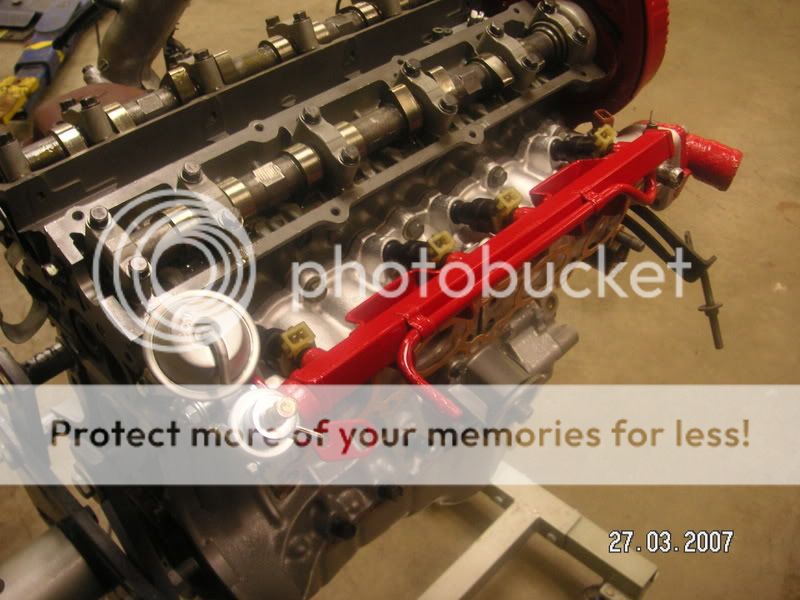

Now theres a good side shot. Fuel rail, injectors, seals, and o-rings all installed.

Heres a good look at the Butterfly Vacuum Actuator and Nismo Adj Fuel Regulator. I tested the vacuum pot and it held vacuum so i can assume it is still in good condition. I also replaced the phillips type bolts with hex head style for increased strength. These little suckers dont like to come out when they've been sitting in there for years and years.

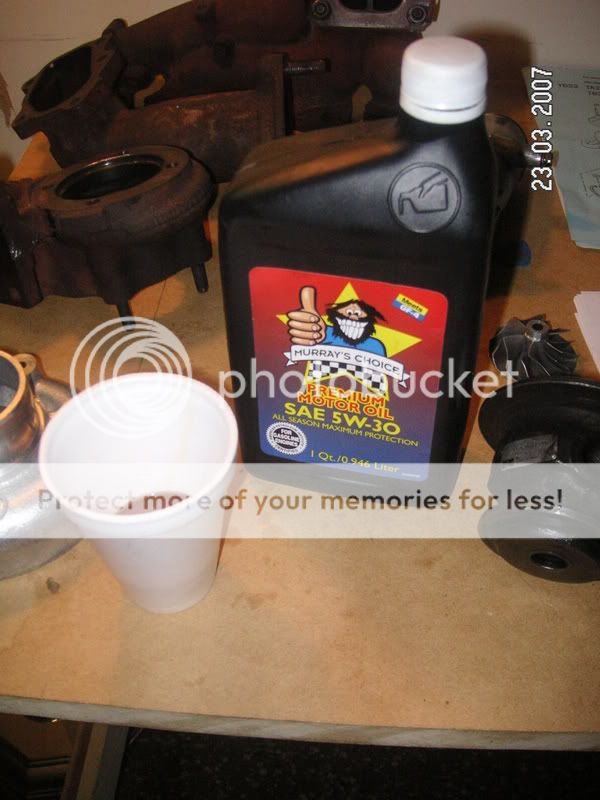

Heres the original 370cc injectors that came with my motorset. I did a resistance check, replaced the o-rings, replaced the other rubber grommet, and made sure they were clean from any obstructions or clogs. I could have had them sent out to have them further tested and balance test, etc. but i didnt think i should be too worried as these arent that expensive to replace. Before i put them into the fuel rail, i made sure there was no debris inside and put a little bit of oil on the o-rings to ease them in.

Stock fuel system will do, for now.

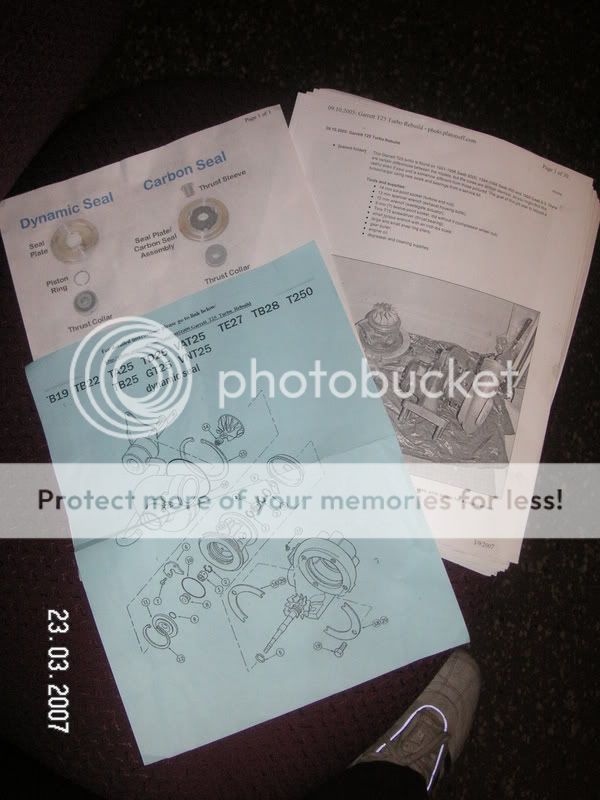

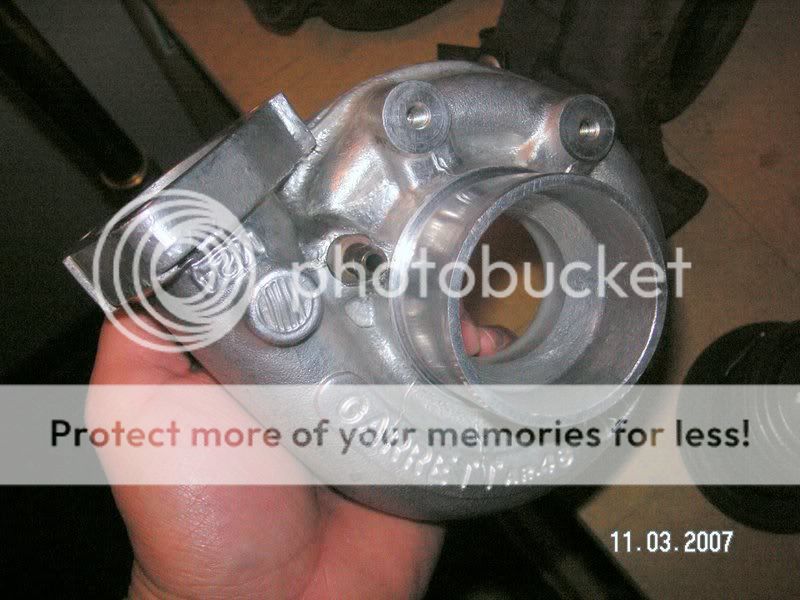

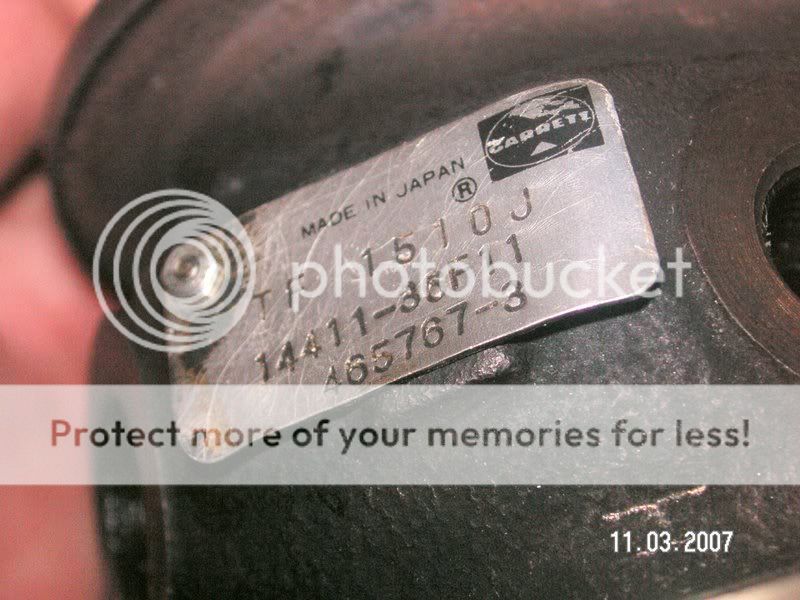

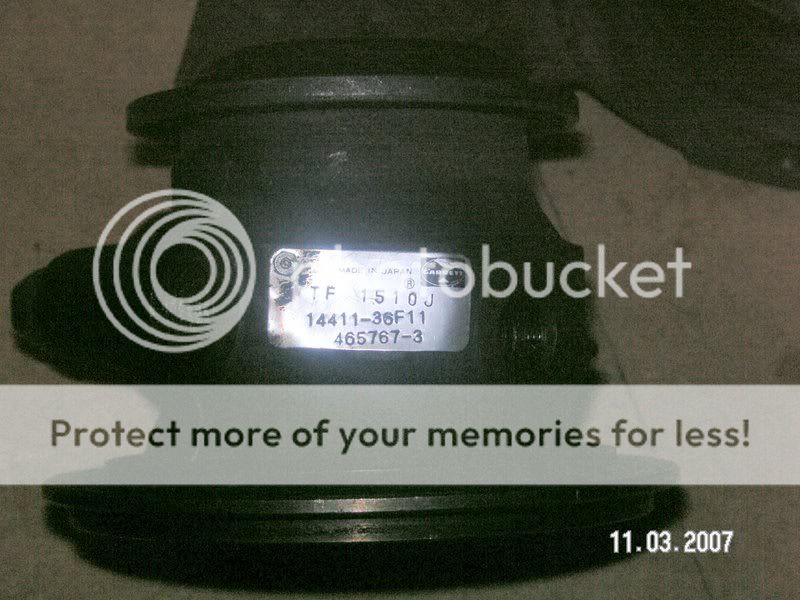

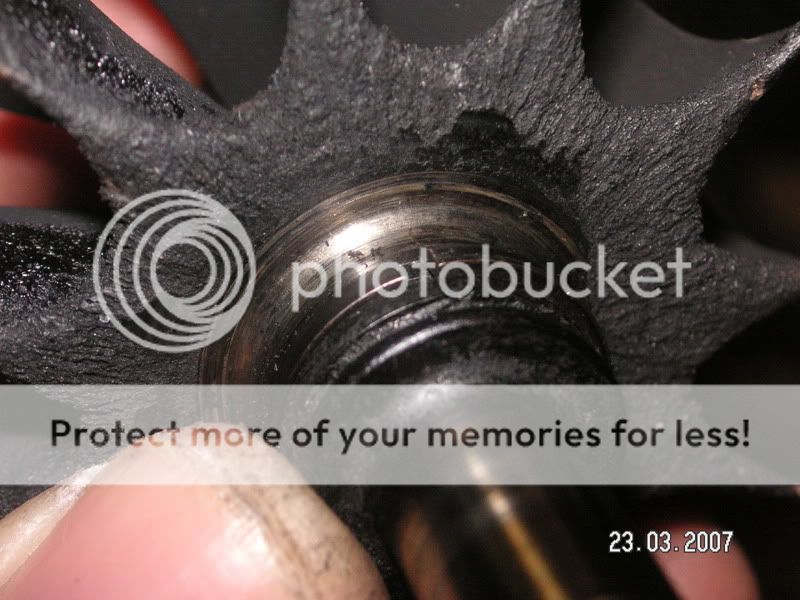

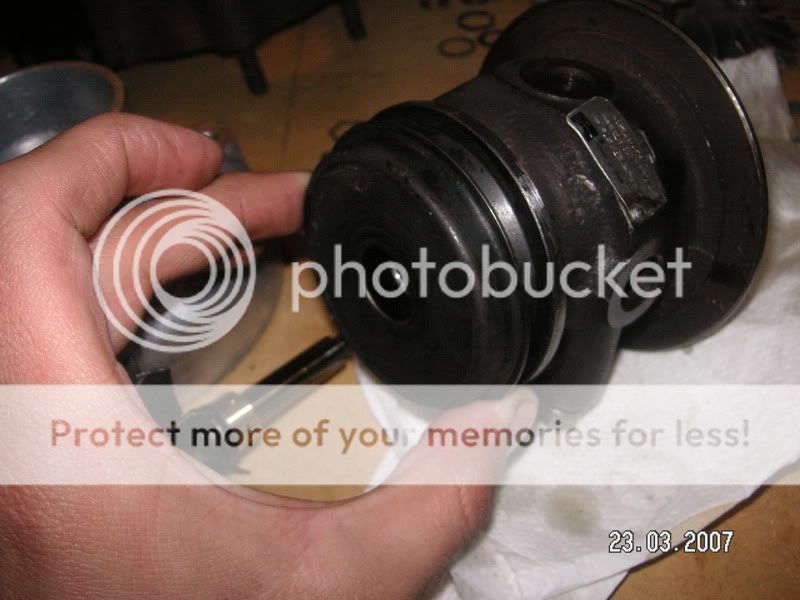

Theres my rebuilt CA T25 and manifold. I rebuilt it myself using common tools and instructions i found online. Before this, i had never done this so it'll be good to see what happens. If it all blows and fails, well i wont feel so bad as it didnt cost me much and it was a great learning experience. I made marks and lined up the compressor wheel and turbine wheel so i think ill be ok. Ive heard that these things were balanced by Garrett individually piece by piece or as an assembly. Im just hoping to get a few thousand miles out of it and then comes an upgrade. Ill post any news if anything happens.

Dont you just love that freshly rebuilt engine smell...

Backside view of the exhaust housing and turbine wheel. Plans for the turbo are Taka SS lines and Megan Racing Outlet and Downpipe.

Rear top view...

Front view...

Another rear-end view?!

Sub-manifold and misc accesories...

Sometimes i take tooooo many pictures...

face

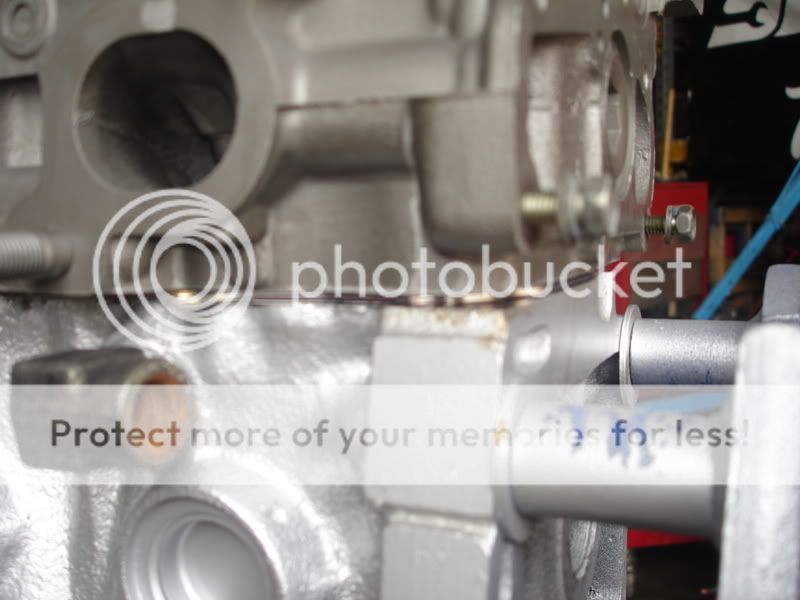

Heres a shot of the cleaned up mating surface for the idle control devices. On the bottom left you can see a part of the idle control valves all cleaned up and ready to go. I also tested the valves/devices according to the FSM and made sure they are within specs. I disassembled the valves and made sure the moving pistons/peices inside were free to move and not sticking. Hopefully this will eliminate any future problems related to idle and warm up.

New gaskets and free moving parts. Those little pistons at the bottom left came from the Auxiliary Air Control valve.

A close up of you know what...

If youre thinking, where the hell are his cam covers, well heres what happened. When i went to pick up all the pieces that i got powdercoated, i looked at the cam covers and refused to use them the way the company left them. The coating was bubbling and flaking off, especially at the flat mating surface where the "ornament" cover goes (c.o.p. cover). They also bubbled up on the top of the covers and were very noticeable. For what i paid, i didnt expect THAT from them. I took them back, talked to the powdercoater, and he agreed he would go back and try again to get them smoother and looking better. I'll post pics later when i get them back.

Side view of motor and manifold setup.

Would there be a risk in not putting back the brackets that come originally on the engine? Has anyone done this(im sure someone has)? Any experience with this?

Some picture i took for some reason i do not remember. I think it was just to show off the red manifold.

There the Idle Air Adjusting Unit, it includes the AAC and FCID.

Under construction...

Modified by davidricardo86 at 6:08 PM 3/29/2007

![Image]()

![Image]()