So after waiting forever for all of the parts, some custom made, some special made to order, I THOUGHT I had all of my ducks in a row but more setbacks. Now that Im actually in the assembly process I will keep track of it with this build thread.

Engine out.

![Image]()

Back from darton. Sleeves are bored to 90mm

![Image]()

![Image]()

K1 stroker crank and rods

![Image]()

![Image]()

Custom forged weisco 10:1 90mm pistons (took 3 months for them to design make and ship)

![Image]()

T3 TWIN SCROLL .82 housing for the 2871r

![Image]()

![Image]()

![Image]()

I am going to be running this on a cast log and we may build a stainless log later on if we decide we would like better turbo placement and to knock the weight down a little. However log manifolds seem to build the quickest spool which is what Im going for with this engine, and log manifolds seem to work with this device called the:

Sound performance quick spool valve

![Image]()

![Image]()

I also made my own maf. Im going blow through on this setup, and I know a standard N62 maf would suffice with this turbo, but I have in the back of my head that ALL I would have to do is swap a turbo and down pipe and a different tune (literally 40 minutes of work) and Im ready to go to the strip. May even get some rear suspension that will squat some and some dr's or wrinkle walls...... but thats later on. Anyways here is what I call a:

P62 maf

![Image]()

![Image]()

Its a p60 housing which is 3.5" with a n62 element inside. I dont know how much power it will support, but probably more than I will need.

Heres a comparison of the p60(p62 actually) compared to the empty n62 housing.

![Image]()

Some pics of my empty head mocked up with manifold, quick spool valve, and custom turbo.

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

Here is the block build

Arp main studs

![Image]()

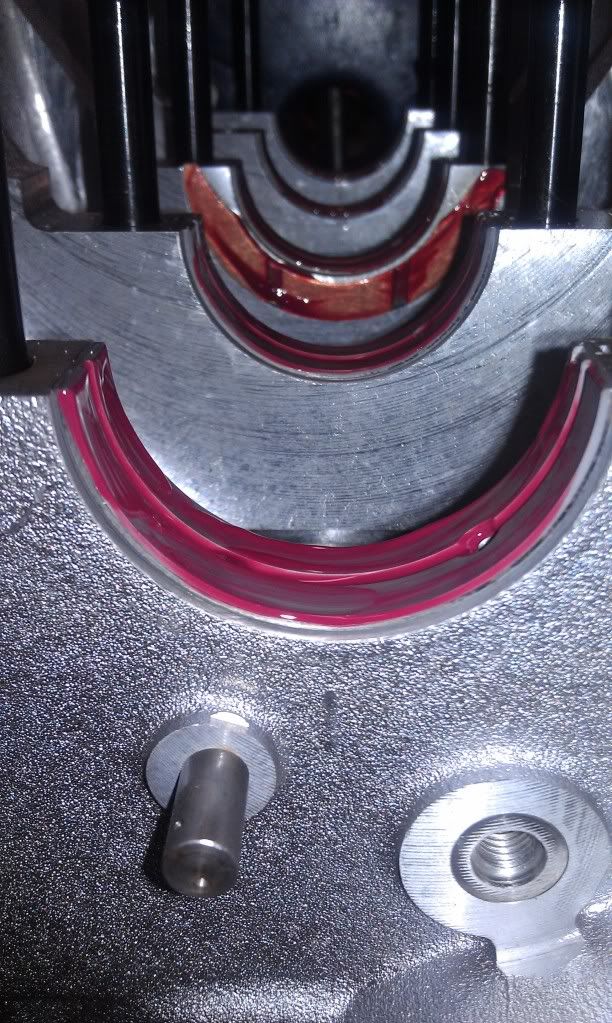

assembly lube

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

Too bad there isnt enough oil clearance. Were going to get to the bottom of this really soon because we put the stock crank in as well and there wasnt enough with it either. Neither would turn well after torquing fully. This is a common problem for people that use arp studs that didnt realize they needed a line hone in order to use them but the arp hardware was sent to darton when they sleeved the block and they were supposedly installed before line honing. If you will notice the lower left of the block in the picture you can see a gouge where it appears to have been dropped. There was raised aluminum in that area that we planed out but its possible that the block shifted some. Im going to call darton because shipping was insured but Im hoping it hasnt been too long to make a claim. Im going to take the bearings, crank(s) block ect to a local machine shop (who balanced and blue printed the rotating assembly) and have them check everything and touch up the line hone if needed. It sucks. I dont want anymore set backs.

Anyways here is a pic of my 38mm v-band tial

![Image]()

Engine out.

Back from darton. Sleeves are bored to 90mm

K1 stroker crank and rods

Custom forged weisco 10:1 90mm pistons (took 3 months for them to design make and ship)

T3 TWIN SCROLL .82 housing for the 2871r

I am going to be running this on a cast log and we may build a stainless log later on if we decide we would like better turbo placement and to knock the weight down a little. However log manifolds seem to build the quickest spool which is what Im going for with this engine, and log manifolds seem to work with this device called the:

Sound performance quick spool valve

I also made my own maf. Im going blow through on this setup, and I know a standard N62 maf would suffice with this turbo, but I have in the back of my head that ALL I would have to do is swap a turbo and down pipe and a different tune (literally 40 minutes of work) and Im ready to go to the strip. May even get some rear suspension that will squat some and some dr's or wrinkle walls...... but thats later on. Anyways here is what I call a:

P62 maf

Its a p60 housing which is 3.5" with a n62 element inside. I dont know how much power it will support, but probably more than I will need.

Heres a comparison of the p60(p62 actually) compared to the empty n62 housing.

Some pics of my empty head mocked up with manifold, quick spool valve, and custom turbo.

Here is the block build

Arp main studs

assembly lube

Too bad there isnt enough oil clearance. Were going to get to the bottom of this really soon because we put the stock crank in as well and there wasnt enough with it either. Neither would turn well after torquing fully. This is a common problem for people that use arp studs that didnt realize they needed a line hone in order to use them but the arp hardware was sent to darton when they sleeved the block and they were supposedly installed before line honing. If you will notice the lower left of the block in the picture you can see a gouge where it appears to have been dropped. There was raised aluminum in that area that we planed out but its possible that the block shifted some. Im going to call darton because shipping was insured but Im hoping it hasnt been too long to make a claim. Im going to take the bearings, crank(s) block ect to a local machine shop (who balanced and blue printed the rotating assembly) and have them check everything and touch up the line hone if needed. It sucks. I dont want anymore set backs.

Anyways here is a pic of my 38mm v-band tial